Gear pumps operate by pressurizing the fluid between the trapped air volume of the meshing teeth of a gear set and the inside wall of the gear housing, then expelling that fluid. Gear: Gear pumps are typically the most inefficient of the three pump types, but are more agreeable with larger amounts of contamination. The typical viscosity range for piston pumps is 15 to 160 cSt at operating temperatures.

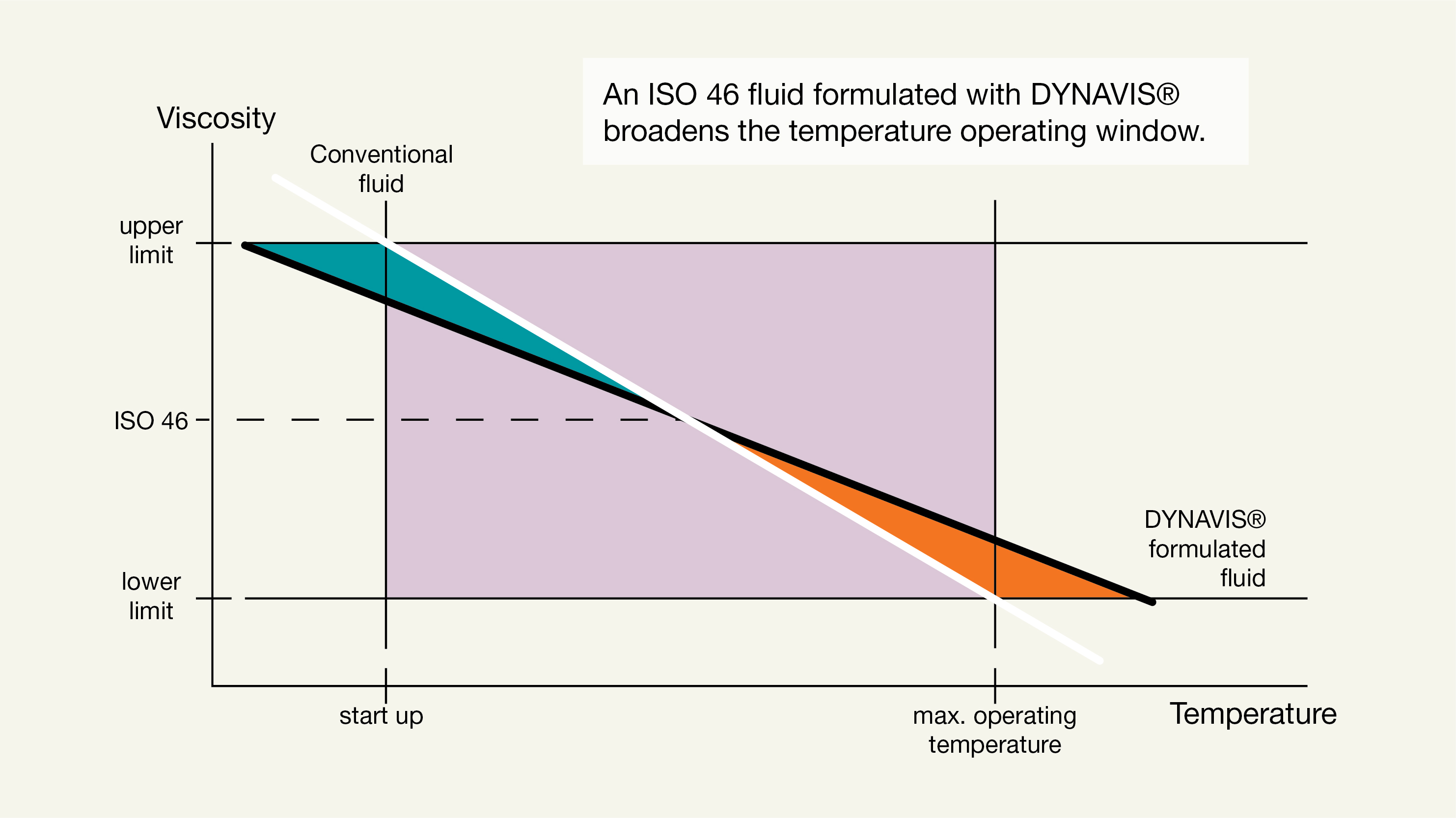

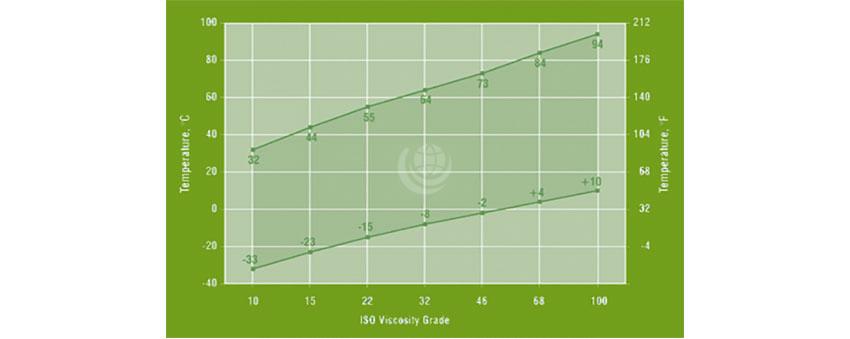

Piston: Piston pumps are your typical middle-of-the-road hydraulic pump, and are more durable in design and operation than a vane pump they can produce much higher operating pressures, up to 6,000 psi. Vane pumps typically require a viscosity range of 14 to 160 centistokes (cSt) at operating temperatures. As the rotors and vanes spin within the ring, the vanes become worn due to the internal contact between the two contacting surfaces.įor this reason, these pumps are typically more expensive to maintain, but they are very good at maintaining steady flow. Inside the pump, there are rotors with slots mounted to a shaft that is spinning eccentrically to a cam ring. Vane: The design of a vane pump is exactly what its name depicts. Each pump type must be treated on a case-by-case basis for lubricant selection. There are three major design types of pumps used in hydraulic systems: vane, piston and gear (internal and external), and each of these pump designs are deployed for certain performance tasks and operations. While they offer good protection from fire, they do lack on wear protection abilities.įigure 1. They are more expensive than petroleum but less expensive than synthetics. These fluids are typically needed where there is a high probability of fire. Water-based fluids are the least common of the fluid types. These fluids offer a lower-cost alternative to synthetics and can be very comparable in performance when certain additive packages are included. There are some disadvantages to these fluids, including high cost, toxicity and potential incompatibility with certain seal materials.Ī petroleum (mineral) fluid is a more common fluid and is made from refining crude to a desired level to achieve better lubricant performance with the inclusion of additives, which range from anti-wear (AW), rust and oxidation inhibitors (RO) and viscosity index (VI) improvers. These fluids are great choices where high or low temperatures are present and/or high pressures are required.

#Hydraulic oil viscosity chart full

It can range from full synthetic (to handle drastic temperature and pressure swings) to water-based fluids (used in applications where there is a risk of fire).Ī synthetic fluid is a manmade chain of molecules that are precisely arranged to provide excellent fluid stability, lubricity and other performance-enhancing characteristics. The chemical makeup of a hydraulic fluid can take many forms when selecting it for specific applications. These roles range from a heat transfer medium, a power transfer medium and a lubrication medium.

Hydraulic fluid has many roles in the smooth operation of a well-balanced and designed system. Selecting the best product for your system requires that you collect and utilize all available information.Īn anti-wear hydraulic oil ofhigh viscosity index base oils with low pour points for wide temperature range applicability, like CITGO’s Mystik® JT-9™ LeakShield® AW Hydraulic Oil, would make a great fit for various hydraulic systems.

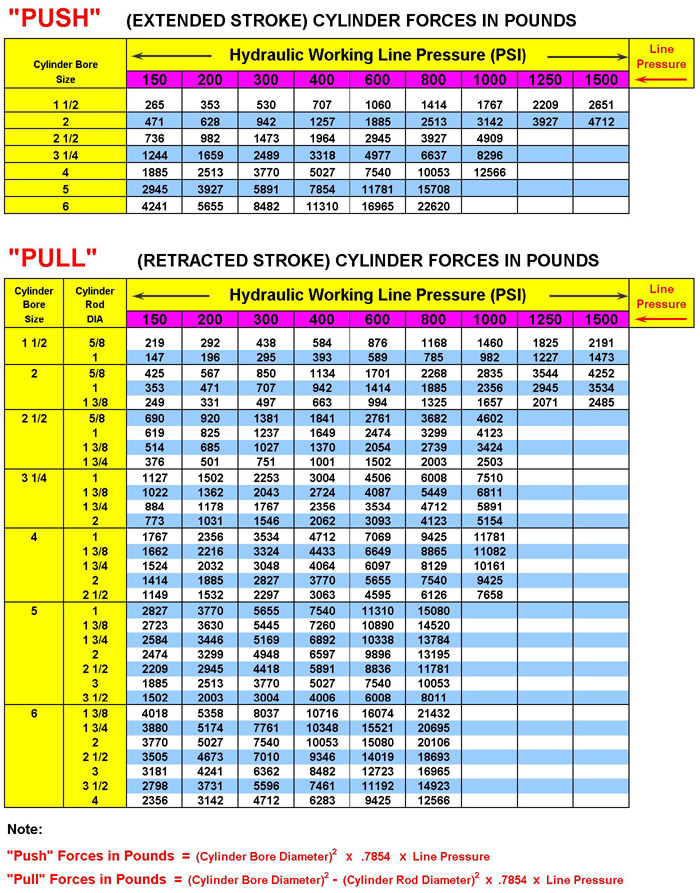

These specifications are typically determined by the type of hydraulic pump employed in the system, the operating temperature and the system’s operating pressure. With hydraulics, there are two primary considerations – the viscosity grade and the hydraulic oil type ( AWor R&O). Most lubricant misspecifications don’t lead to sudden and catastrophic failure rather, a misspecification shortens the average life of the lubricated components or decreases efficiency over time and, thus, goes unnoticed. Just because a machine will run with a particular product doesn’t mean that product is optimum for the application. For most lubricated machines, there are many options when it comes to lubricant selection.

0 kommentar(er)

0 kommentar(er)